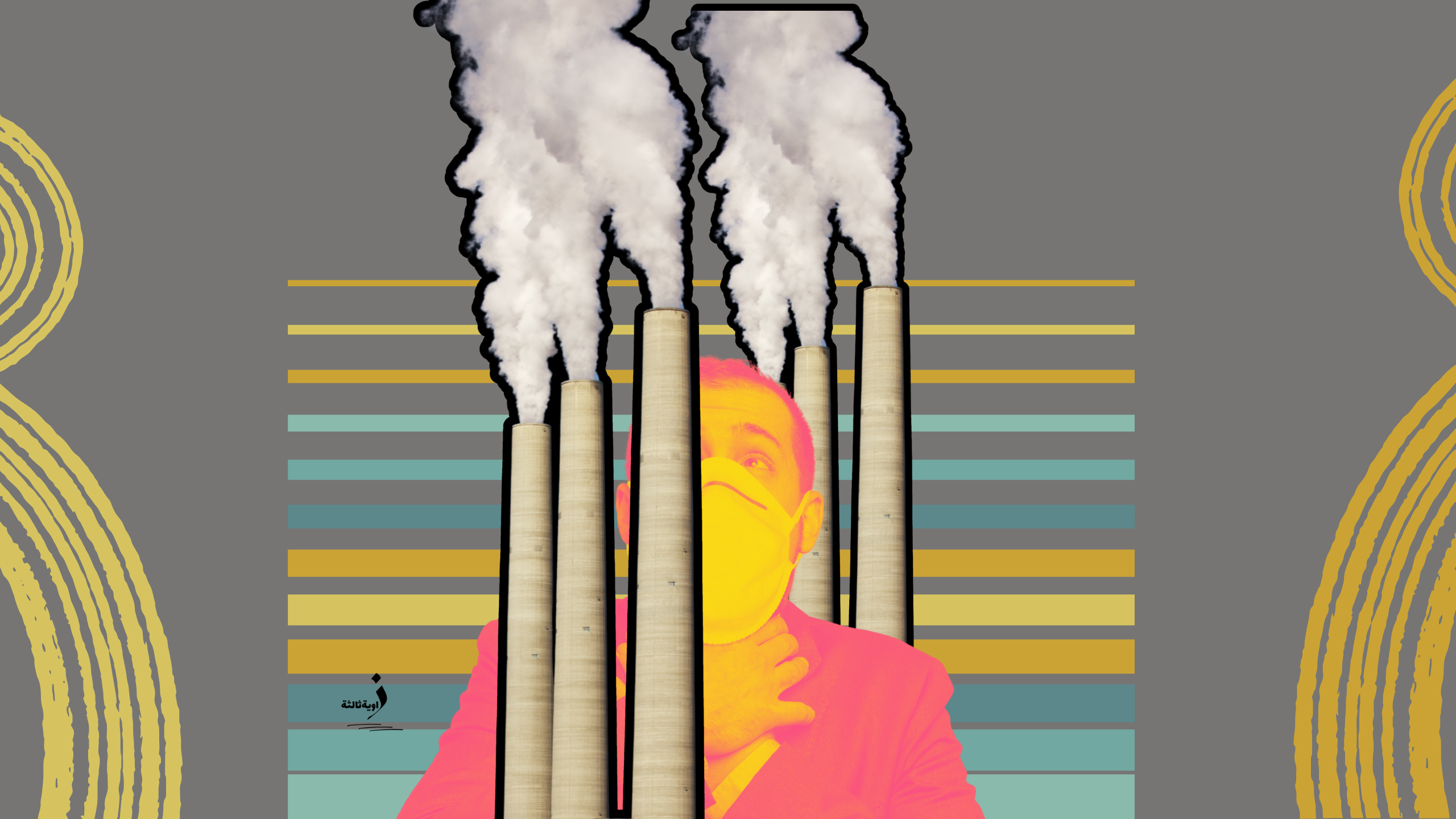

At 5 a.m., Ms. Mas’ada Abdel-Hay, a 64-year-old woman, sits on the rooftop of her house in the village of Al-Fuwaireeqa, located in the Abu Qurqas district, south of Minya Governorate. She cautiously breathes in some fresh air in an attempt to avoid the looming threat of death from the smoke emanating from the sugar factory day after day.

Mas’ada contracted asthma early on due to the proximity of her home to the factory. She is not the only one in the village suffering from the devastating effects of the sugar factory. Hundreds of residents in the village suffer from respiratory diseases and allergies, including asthma, kidney failure, and cancer. The factory poses a threat to their lives due to the disposal of its gaseous, liquid, and solid waste in an area inhabited by around 30,000 people.

Mas’ada contracted asthma early on due to the proximity of her home to the factory

According to a Zawia3 field investigation among the residents of Al-Fuwaireeqa village, this inquiry reveals cases of disease outbreaks and contamination of the watercourse surrounding the factory along its stretch. Additionally, it documents the reckless endangerment of citizens’ lives through the irrigation of nearly 100 acres with liquid waste emanating from the factory, along with the suffering of thousands of Al-Fuwaireeqa residents.

In this area, Mrs. Gamalat recalls a time when the factory operated with wood and straw nearly 70 years ago, where the black cloud polluted the air, and ash fell on house roofs and passersby. Despite the factory no longer using wood and straw, the ash still accumulates on house floors due to the dispersion of impurities during boiling. Gamalat summarizes, as she sits on the doorstep of her house in a narrow alley near the factory, the environmental conditions they grew up in, without anyone paying attention to them.

In December 2022, the Ministry of Environment announced the completion of the environmental remediation plans for the Abu Qurqas Sugar Company, financed by the Industrial Pollution Control Program (Phase III) under the Ministry of Environment. According to the report, the Ministry signed a grant agreement for cooperation with the European Union worth four million euros, as part of the funding for Phase III of the Industrial Pollution Control Program (EPAP), with a budget of 145 million euros, implemented in collaboration with the European Union, the European Investment Bank, the French Development Agency, and the German Reconstruction Bank.

Magdy Allam, Secretary-General of the Arab Environmental Experts Union and a consultant to the Global Environment Facility, tells Zawia3 in a statement that the Ministry of Environment has received many international grants to reduce factory pollution. He explains that the liquids discharged from the factory will cause very significant environmental damage, saying, “We are talking about carbon oxides, nitrogen oxides, and sulfur oxides. These substances result from heating and evaporation processes inside the factory, and it is essential to have treatment to dispose of the chemicals.”

![]()

Mosquitoes and a black cloud

“Nobody pays attention to the area’s residents” says Mrs. Gamalat

Thousands of miles away from the factory, one can still smell a very foul odor,” says Faheya, a vegetable seller in a corner near the factory, about the foul smell that emanates throughout the day due to heating and evaporation processes. She says that although it is extremely repulsive, they have become accustomed to it, and only outsiders to the village feel repelled by it. However, she points out that the significant harm is not just in the smell but in the mosquitoes that breed from it, as “mosquitoes disrupt our lives” in the summer, and the problem does not stop at the inability to get rid of them. It causes the spread of many diseases among children and women due to excessive sensitivity, as they are forced to use insecticides in every corner of their homes, even on the vegetables she sells to prevent mosquito infestation. Thus, the factory emits a foul odor due to the gaseous waste it leaves behind.

Law No. 4 of 1994 stipulates that any alteration in the characteristics and specifications of natural air that may pose a risk to human health or the environment, whether such pollution is due to natural factors or human activity, including foul odors, whether solid, liquid, or gaseous, and the punishment is determined by the executive regulations of this law.

In agreement with Mohammed Gamal, one of the factory workers, he conducted a photographic tour from inside the factory, explaining how sugar production processes are carried out. He begins with purifying sugar beet slices in tanks filled with hot water, and the washing process involves the use of thousands of liters of water, as the factory operates with a capacity of up to 10,000 tons per day during the season.

In addition to washing with water, alkaline substances such as caustic soda or “bicarbonates” are added to clean the beets and remove organic dirt and grease, especially since beet cleaning requires double the effort of cane cleaning because the outer skin of the beet is very sticky. Then the beets undergo a heating and evaporation process where part of it turns into sugar, part into liquid, and part evaporates, with the volatile substances exiting in the form of a black cloud, while the liquid substances pour from the factory’s rear gate to a point called the “ocean,” which is a watercourse adjacent to the freshwater irrigation channel.

![]()

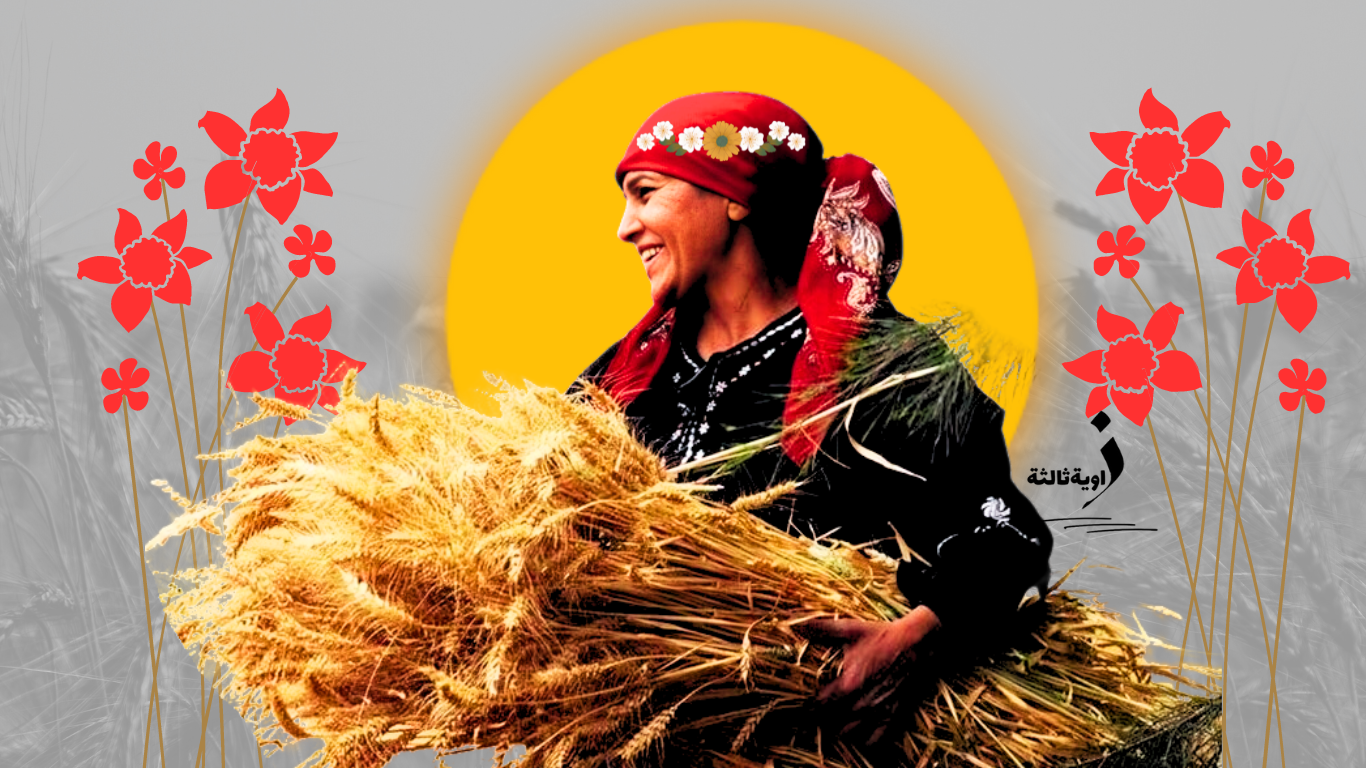

Deadly Factory Water Irrigation

Across the adjacent lands, several farmers tell us that they use water from the factory for irrigation, as often irrigation water is not available, so they resort to using the sewage water discharged from the factory, which extends along the agricultural lands. Ashraf Hamdi says they have been using sewage water for many years, and they have only noticed a change in crop quality in recent years.

It’s worth mentioning that freshwater channels have only recently entered the Al-Fuwaireeqa area or the neighboring villages, and water is not permanently available, making farmers heavily rely on water from the factory adjacent to irrigate along the agricultural lands.

A source from the Ministry of Agriculture, preferring not to mention his name, explains in his conversation with “Zawia3” that what is happening at the sugar factory is an environmental crime. The liquid waste exiting from the factory gate forms a parallel channel along the agricultural road, leaving a disastrous impact on the soil, causing malignant diseases and kidney failure, and threatening food security in the long run. He emphasizes that the responsibility of irrigating land with polluted water falls on the Land and Water Department of the Agriculture Directorate, and on the Ministry of Environment in accordance with Article 4 of 1994.

A study by the United Nations Development Program in 2010 indicates that exposure to unintentional persistent organic pollutants poses many health threats, including respiratory problems, skin disorders, acute brain damage, stroke, asthma, coughing, bronchitis, reduced lung growth, and high blood pressure. Workers handling this waste are at significant risk because they directly touch hazardous materials.

According to a statement from the Ministry of Environment issued in 2017 to discuss the problem, it confirms that the Abu Qurqas Sugar Factory disposes of its waste resulting from the use of sugar beet and sugar cane crops in sugar and other products in a drainage channel called the “Ocean,” increasing the pollution rate of its water with chemicals. Factory waste is discharged from a point near the “Atlidem” drainage, which is close to the factory, to the “Ocean” drainage at a rate of up to five thousand cubic meters per day.

Abdul Galil explains that the watercourse carrying all the waste and heavy elements is directed towards the coastal governorates, as watercourses coming from southern factories converge in one spot, which is the “Atlidem” drainage north of Minya Governorate, and from this point, the pollution level in the water increases significantly.

According to Article 2 of the Nile River Protection Law No. 48 of 1982, the disposal or dumping of solid, liquid, or gaseous waste from industrial facilities into watercourses along their entire lengths and areas is prohibited. Article 3 stipulates that health authorities must periodically analyze samples of liquid waste, and if it is found that the samples violate the standards that preserve human health, the license must be immediately withdrawn from the concerned party.

![]()

Decay in the Soil

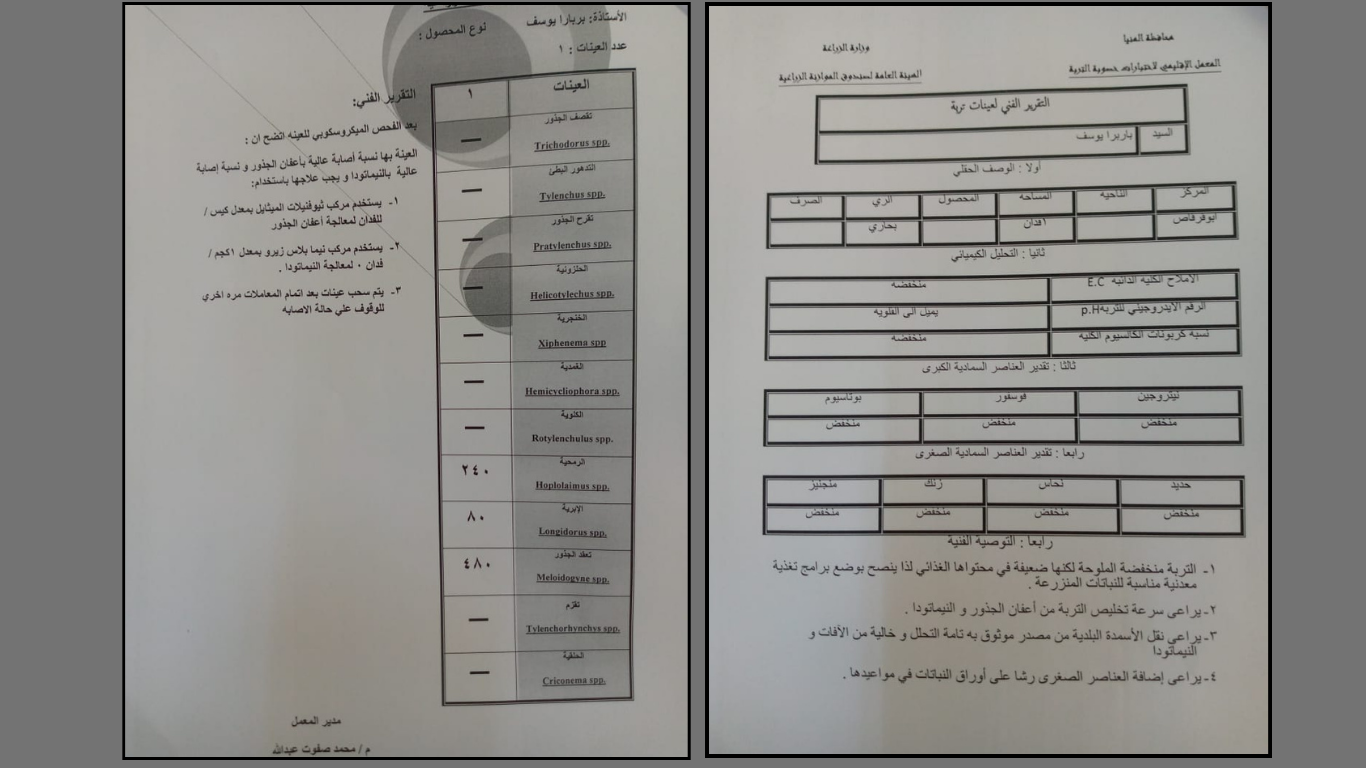

In collaboration with agricultural engineer Mufdi Zaki, we took soil and water samples surrounding the factory and had them analyzed at the Agriculture Directorate. The results of the reports indicated the presence of decay in the soil, with nematodes spreading within it. Their presence serves as an indicator of water pollution with phosphates and chemicals, further enhancing the danger to the environment surrounding the factory and its negative impact on the soil and nearby water.

Mohammed Safwat, the manager of the Soil Fertility Laboratory at the General Authority for Budget Affairs, explains that decay resulting from the excessive use of chemicals causes crop losses of up to 30%. He points out that the soil is deeply affected over the years due to the use of chemicals, as liquid toxins and chemical elements do not decompose in the soil but rather accumulate and remain underground, leading to devastating long-term effects.

In an attempt to communicate with the relevant authorities to clarify the matter, Essam Amer, the head of the Regional Branches Sector for Environmental Affairs, confirmed that the ministry has not received any funding for factory development since 2011, and all activities have ceased. This contradicts multiple statements coming from the ministry’s official page and international entities, which affirm that the Environmental Sector has received funding for environmental reform, and the ministry insists that the Abu Qurqas Sugar Factory has already been repaired, raising questions about the actual status of the factory and its potential impact on the residents of Al-Fuwaireeqa village.

Amidst this tragic reality of the residents’ suffering and denial statements, more than 30,000 people in Al-Fuwaireeqa village live in a state of neglect under direct health threats, while thousands of others live under the threat of water and land contaminated with pesticides. Effective human protection is incomplete without protecting the environment in which they live. We cannot protect the environment unless we target pollution sources and address them effectively and decisively.